![]()

![]()

*** The Axtrack Vehicle System is up for sale as a package ***

It is a unique system with a 40 year history and reliability record. It can be built with very simple equipment and can be adapted to local content. The final drive/steering system is entirely mechanical, and when coupled with appropriate engines and transmissions, will give far better fuel economy and higher speeds than hydraulic or hydrostatic drives at a substantially lower cost. It is easy to scale up or down. Compared to the plethora of 6 and 8 wheel drive ATV's on the market, the earlier, smaller Axtracks, with steering clutches and reliable suspensions are not nearly as maintenance intensive. They will carry heavier loads, faster. In short, they are not toys or recreational vehicles, they can be used commercially. If you are interested in exploring the market potential of a vehicle of this type, and developing or adapting a full rubber track for use in all seasons, consider looking at the Axtrack. The package includes a short wheel base, rear drive vehicle, with a spare set of tracks, blue prints, injection molds for the suspensions, all the patterns required for the geared final drives, molds for coating the track drive sprockets, sets of gears, castings, track components and spare early clutches, and more.

The first Axtrack, built in 1973 and still being used in Falls Creek. It just fits into a 6 foot wide tandem trailer for easy transport. Empty weight was about 680 kg / 1500 lbs.

The first Axtrack, built in 1973 and still being used in Falls Creek. It just fits into a 6 foot wide tandem trailer for easy transport. Empty weight was about 680 kg / 1500 lbs.

Rear view of Axtrack, showing low access height, ample space for 6 passengers. Carrying capacity about 1600 pounds or generally whatever would fit on.

Rear view of Axtrack, showing low access height, ample space for 6 passengers. Carrying capacity about 1600 pounds or generally whatever would fit on.

Access to VW 1500 engine and four speed gearbox. Steering was achieved by drum brakes individually controlled. With a top speed over 70 kph or 45 mph the vehicle was frighteningly fast.

Access to VW 1500 engine and four speed gearbox. Steering was achieved by drum brakes individually controlled. With a top speed over 70 kph or 45 mph the vehicle was frighteningly fast.

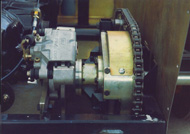

Looking for lighter and more rigid construction methods, the first monocoque body was built in the early 1980's. Instead of the VW motor there was now a Nissan Sunny 1400, coupled to the inevitable VW gearbox. A chain drive was used to reduce the speed, and connected the VW axles forward to the track drive shafts, which each had a substantial disc brake fitted. There were now 4 wheels on each side, mounted on the leading arm suspension as in the previous chassis models. This moved the centre of gravity back, and greatly improved the stability of the vehicle under brakes.

Looking for lighter and more rigid construction methods, the first monocoque body was built in the early 1980's. Instead of the VW motor there was now a Nissan Sunny 1400, coupled to the inevitable VW gearbox. A chain drive was used to reduce the speed, and connected the VW axles forward to the track drive shafts, which each had a substantial disc brake fitted. There were now 4 wheels on each side, mounted on the leading arm suspension as in the previous chassis models. This moved the centre of gravity back, and greatly improved the stability of the vehicle under brakes.

Massive carrying capacity in the rear, 75 mm/ 3 inches wider across the floor because of the monocoque construction, for the same overall vehicle width. Note: track adjusters at floor level.

Massive carrying capacity in the rear, 75 mm/ 3 inches wider across the floor because of the monocoque construction, for the same overall vehicle width. Note: track adjusters at floor level.

Eager to improve the turning performance and eliminate the brake through differential steering, the designer invented an entirely new clutch system. Each track was now individually driven, through a hydraulically controlled clutch, with a disc brake mounted in tandem. The result was outstanding. The clutches are light and simple, and use disc brake pads for linings. Wear is virtually non-existent. Climbing a steep slope with a full load, there is no change in engine pitch when turning.

Eager to improve the turning performance and eliminate the brake through differential steering, the designer invented an entirely new clutch system. Each track was now individually driven, through a hydraulically controlled clutch, with a disc brake mounted in tandem. The result was outstanding. The clutches are light and simple, and use disc brake pads for linings. Wear is virtually non-existent. Climbing a steep slope with a full load, there is no change in engine pitch when turning.

Pedal arrangement for the clutches, consisting of clutch, brake, and accelerator. Note: heel rests under clutch and accelerator pedals. Very useful when going down steep slopes! The brake pedal pulls on both disc brake master-cylinders through the central toggle, but is overridden when the steering levers are used, which can add pressure to either side when braking and steering down steep slopes. Note: positions for 4 master-cylinders. Bottom two for brakes, top two for clutches. The two steering levers control both pairs. The inevitable VW gearbox, now with a locked differential, still provides the transmission.

Pedal arrangement for the clutches, consisting of clutch, brake, and accelerator. Note: heel rests under clutch and accelerator pedals. Very useful when going down steep slopes! The brake pedal pulls on both disc brake master-cylinders through the central toggle, but is overridden when the steering levers are used, which can add pressure to either side when braking and steering down steep slopes. Note: positions for 4 master-cylinders. Bottom two for brakes, top two for clutches. The two steering levers control both pairs. The inevitable VW gearbox, now with a locked differential, still provides the transmission.

The first Axtrack fitted with steering clutches read for the cabin. Note: the hefty "A" bar in front of the engine. That is the secret of the incredible torsional rigidity of the Axtrack. There have never been any cracks in the body-work.

The first Axtrack fitted with steering clutches read for the cabin. Note: the hefty "A" bar in front of the engine. That is the secret of the incredible torsional rigidity of the Axtrack. There have never been any cracks in the body-work.

The Axtrack with the first body fitted. All steel cab, with semi rigid roof for the rear, for quick removal. Cab also removes quickly for maintenance, or for use as an open vehicle.

The Axtrack with the first body fitted. All steel cab, with semi rigid roof for the rear, for quick removal. Cab also removes quickly for maintenance, or for use as an open vehicle.

The Axtrack showing its mettle during Police Search and Rescue training exercises. It was used by PS&R for 17 years, and is now at home at Falls Creek, where it was used by a supermarket for deliveries for 4 or 5 years. When the supermarket changed hands, the Axtrack went to a private buyer who owns a commercial lodge.

The Axtrack showing its mettle during Police Search and Rescue training exercises. It was used by PS&R for 17 years, and is now at home at Falls Creek, where it was used by a supermarket for deliveries for 4 or 5 years. When the supermarket changed hands, the Axtrack went to a private buyer who owns a commercial lodge.

Aluminium cab under construction for the Victorian Alpine Resorts Commission during the early 1980's. The light superstructure gave frightening side-slope capability.

Aluminium cab under construction for the Victorian Alpine Resorts Commission during the early 1980's. The light superstructure gave frightening side-slope capability.

The finished vehicle at Mount Stirling, where it was used for many years setting tracks and compacting snow for cross country skiers. It was later transferred to another mountain resort in Victoria, Mount Baw Baw, where it has remained to this day. It is currently being restored and will give many more years of use.

The finished vehicle at Mount Stirling, where it was used for many years setting tracks and compacting snow for cross country skiers. It was later transferred to another mountain resort in Victoria, Mount Baw Baw, where it has remained to this day. It is currently being restored and will give many more years of use.

A short and long wheel base Axtrack near the summit of Mount Stirling, Victoria, during trials. The view is towards Mount Buller. Wherever the Axtrack vehicles appeared, there was always controversy about which was superior, rear driven tracks or front driven. The Axtrack Co. spent considerable resources building and trialing both systems, and very quickly worked out why the front driven vehicles all seemed to have the motor right in the middle of the vehicle, with the resultant lack of carrying capacity.

A short and long wheel base Axtrack near the summit of Mount Stirling, Victoria, during trials. The view is towards Mount Buller. Wherever the Axtrack vehicles appeared, there was always controversy about which was superior, rear driven tracks or front driven. The Axtrack Co. spent considerable resources building and trialing both systems, and very quickly worked out why the front driven vehicles all seemed to have the motor right in the middle of the vehicle, with the resultant lack of carrying capacity.

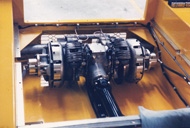

The Axtrack final drive unit installed in a rear drive Axtrack. There are several final drive ratios available, and there is a worm drive centre, or conventional crown wheel and pinion centre, depending on the ratio required or whether for front or rear drive. There is room for a wide range of engines and manual or automatic transmissions.

The Axtrack final drive unit installed in a rear drive Axtrack. There are several final drive ratios available, and there is a worm drive centre, or conventional crown wheel and pinion centre, depending on the ratio required or whether for front or rear drive. There is room for a wide range of engines and manual or automatic transmissions.

All the later model Axtracks used specially designed and built suspension units, because Axtrack wanted to do it better. The units have an extremely wear resistant plastic bush running on a chrome sleeve, to take the track tension and control the wheel alignment, unlike some of the larger manufacturers who use the "Flexator" system, and weld a steel steady plate on the end, which wears through the shaft. The unit is injection molded by Mackay Rubber Pty Ltd., and has been extremely reliable. If damaged it is quick and easy to replace.

All the later model Axtracks used specially designed and built suspension units, because Axtrack wanted to do it better. The units have an extremely wear resistant plastic bush running on a chrome sleeve, to take the track tension and control the wheel alignment, unlike some of the larger manufacturers who use the "Flexator" system, and weld a steel steady plate on the end, which wears through the shaft. The unit is injection molded by Mackay Rubber Pty Ltd., and has been extremely reliable. If damaged it is quick and easy to replace.

An Axtrack suspension unit fitted to an Axtrack. This system will give up to 100 mm / 4 inches of travel. Shorter and longer arms can be fitted. Many of these suspensions have been fitted to caravans, as well as boats and car trailers. The author has personally used a trailer fitted with these suspensions since 1990, and carried some serious loads.

An Axtrack suspension unit fitted to an Axtrack. This system will give up to 100 mm / 4 inches of travel. Shorter and longer arms can be fitted. Many of these suspensions have been fitted to caravans, as well as boats and car trailers. The author has personally used a trailer fitted with these suspensions since 1990, and carried some serious loads.

Email: info@axtrack.com.au